In the ever-evolving landscape of manufacturing, the demand for efficient heat dissipation solutions has never been greater. As industries continue to push the boundaries of technological advancements, the need to manage heat generated by electronic components becomes increasingly critical. One such solution that has gained immense popularity is the CNC machining square heat sink.

This article delves into the intricacies of CNC machining square heat sinks, shedding light on their design, manufacturing process, and the numerous advantages they offer. Join us on this journey as we explore the world of precision and efficiency in thermal management.

Understanding CNC Machining Square Heat Sinks

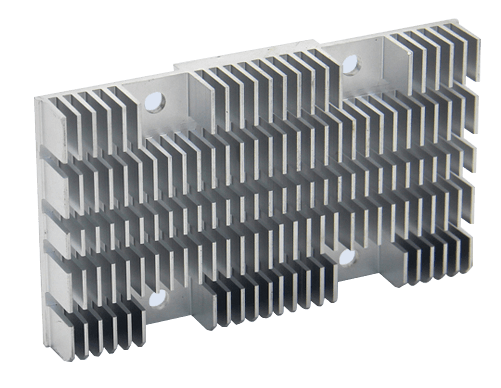

CNC machining square heat sinks are precision-engineered cooling components that play a vital role in dissipating heat generated by electronic devices. These heat sinks are meticulously designed to maximize surface area, enhance airflow, and promote efficient heat transfer, ensuring the optimal functioning and longevity of electronic components.

The Design Process: A Symphony of Engineering and Precision

The design of a CNC machining square heat sink is a careful interplay of engineering principles and meticulous precision. Let's explore the key steps involved in creating a heat sink that delivers exceptional thermal performance.

Thermal Analysis

The design process commences with a thorough understanding of the specific thermal requirements of the electronic device. Factors such as power dissipation, operating environment, and temperature limitations are meticulously analyzed to determine the optimal thermal solution.

Material Selection

Choosing the right material is paramount in achieving efficient heat dissipation. Aluminum and copper alloys are widely preferred due to their excellent thermal conductivity, corrosion resistance, and lightweight properties. The selection of the appropriate material depends on various factors, including the desired thermal performance and cost considerations.

Geometry and Fin Design

The geometry of the heat sink and the arrangement of fins significantly impact its thermal efficiency. Fins increase the surface area, allowing for better heat dissipation. The shape, size, and spacing of fins are carefully designed using advanced CAD software and computational fluid dynamics (CFD) simulations to optimize cooling performance.

Manufacturing

Once the design is finalized, the manufacturing process begins. CNC machining, known for its precision and versatility, is often employed to fabricate square heat sinks. This process involves the use of computer-controlled machines that precisely remove material from a solid block, resulting in intricate and accurate heat sink components.

CNC Machining Square Heat Sink

Advantages of CNC Machining Square Heat Sinks

CNC machining square heat sinks offer a multitude of advantages that make them highly sought-after in various industries. Let's explore the key benefits that set them apart from other heat dissipation solutions.

Superior Thermal Performance

The precision engineering of CNC machining square heat sinks ensures optimal thermal performance. By maximizing surface area and promoting efficient airflow, these heat sinks effectively dissipate heat, preventing overheating and ensuring the longevity of electronic components.

Customizability and Design Flexibility

CNC machining allows for intricate designs and complex geometries, enabling the customization of heat sinks to suit specific applications. Whether it's the shape, size, or fin arrangement, CNC machining offers unparalleled design flexibility, ensuring that each heat sink is tailored to meet the unique thermal requirements of the electronic device.

Excellent Mechanical Stability

Apart from their exceptional thermal performance, CNC machining square heat sinks also provide mechanical stability and structural integrity. The high-precision manufacturing process ensures that the heat sink can withstand demanding operational conditions while maintaining its effectiveness in heat dissipation.

Cost-effective Production

CNC machining square heat sinks offer cost-effective production solutions in comparison to other manufacturing methods. The ability to create intricate designs in a single manufacturing step minimizes material waste and reduces the need for additional assembly processes. This streamlined production approach translates to cost savings and improved efficiency for manufacturers.

Compatibility with Various Industries

CNC machining square heat sinks find applications in a wide range of industries, including electronics, telecommunications, automotive, aerospace, and more. Their versatility and ability to meet specific thermal requirements make them a preferred choice for cooling electronic components in diverse applications.

Conclusion

CNC machining square heat sinks stand as a pinnacle of precision and efficiency in thermal management. By understanding the intricacies of CNC machining square heat sinks, manufacturers and engineers can unlock the full potential of these remarkable cooling solutions.

.jpg)