In the realm of thermal management, the custom brass heat sink plays a vital role in dissipating excess heat from electronic components. Engineered with precision and designed with purpose, these heat sinks are essential for maintaining the optimal operating temperature of various devices and systems.

Understand The Custom Brass Heat Sink

A custom brass heat sink is a specialized cooling device made from high-quality brass material precisely tailored to suit the thermal requirements of specific applications. Its primary function is efficiently dissipating heat generated by electronic components, such as CPUs, GPUs, power transistors, and LED modules. These heat sinks draw heat away from the source and disperse it into the surrounding environment by employing a combination of thermal conductivity and convective heat transfer.

The Importance of Custom Brass Heat Sinks

Effective thermal management is crucial for the reliable and prolonged operation of electronic systems. Excessive heat can degrade component performance, reduce lifespan, and even lead to catastrophic failures. Custom brass heat sinks play a pivotal role in maximizing thermal efficiency by preventing the overheating of critical components. By efficiently dissipating heat, they ensure the stability, longevity, and optimal functionality of electronic devices.

Types of Custom Brass Heat Sinks

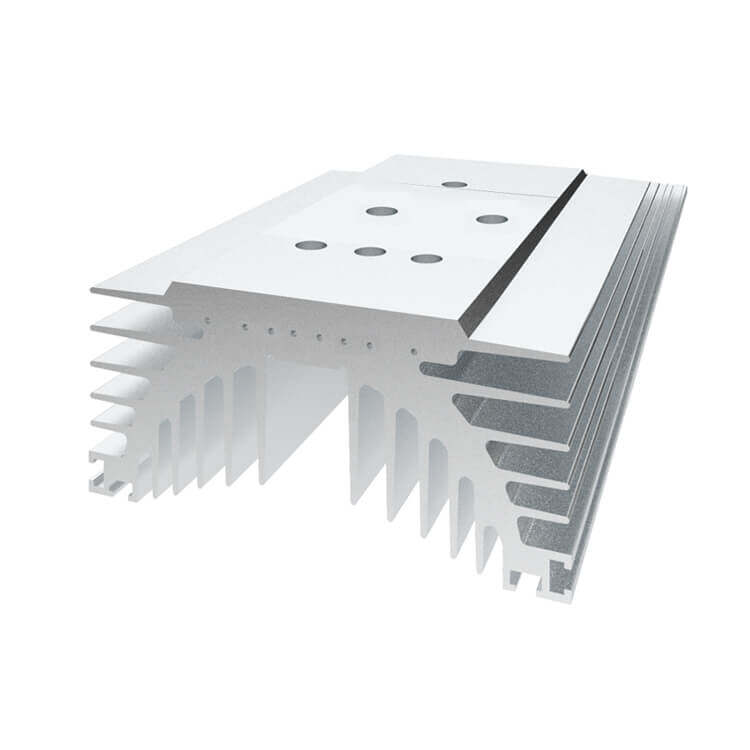

Extruded Heat Sinks

One common type is the extruded heat sink. These heat sinks are created by extruding a brass profile into the desired shape. Extruded heat sinks offer versatility in design and are cost-effective for mass production. They can be customized to meet specific requirements and provide efficient thermal management.

Skived Heat Sinks

Another type of custom brass heat sink is the skived heat sink. Skived heat sinks are manufactured using a precise skiving process, resulting in a thin, lightweight design with excellent thermal performance. These heat sinks are ideal for applications where weight and space are critical factors.

Bonded Fin Heat Sinks

For more specialized applications, bonded fin heat sinks offer an effective solution. They feature fins that are bonded to the base, providing increased surface area for improved heat dissipation. Bonded fin heat sinks are commonly used in high-power electronics and other demanding thermal environments.

Folded Fin Heat Sinks

Similarly, folded fin heat sinks are designed to maximize surface area for enhanced heat dissipation. The fins are created by folding a continuous sheet of brass, creating a compact and efficient cooling solution. These heat sinks are often utilized in applications where space is limited, but high thermal performance is still required.

Factors Influencing Heat Sink Performance

Airflow and Ventilation

The airflow around the heat sink plays a crucial role in heat dissipation. Proper ventilation and strategic placement are necessary to ensure efficient cooling. By allowing a steady flow of air across the heat sink, the transfer of heat to the surroundings is facilitated.

Thermal Interface Materials

The choice of thermal interface material between the heat sink and the component is critical. High-quality thermal interface materials, such as thermal grease or thermal pads, enable optimal thermal conductivity and minimize thermal resistance. By ensuring effective thermal transfer, these materials enhance the overall performance of the heat sink.

Ambient Temperature and Power Dissipation

The ambient temperature and power dissipation within the system should be taken into account when designing custom brass heat sinks. Higher ambient temperatures and increased power dissipation can significantly impact the heat sink's performance. By considering these factors, appropriate measures can be taken to mitigate any adverse effects.

System Design and Integration

Lastly, the overall system design and integration should be carefully evaluated. Factors such as the placement of heat-generating components, airflow restrictions, and the heat sink's interaction with other system elements can impact its efficiency. A comprehensive approach to system design ensures that the heat sink operates optimally within the larger context.

Conclusion

Custom brass heat sinks stand as essential components in the realm of thermal management, enabling the efficient dissipation of excess heat from electronic devices. Their ability to optimize thermal efficiency, prevent overheating, and ensure the reliable operation of critical components makes them worthwhile for ensuring smooth operation.

.jpg)