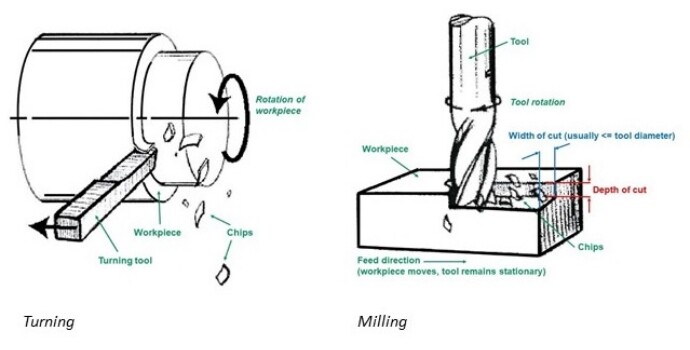

CNC Turning operations are performed by rotating the workpiece and using a stationary cutting tool, and conversely, CNC milling services are performed by rotating the cutting tool and leaving the workpiece locked in place.

The two use different techniques to create a part. Typically, milling machines create complex parts from blocks of metal by carving away the excess material, while CNC turning services are commonly used for cylindrical parts like shafts.

Turn/Mill machines require only one set-up. That means less time and less handling, which leads to more production.

Jiesheng Hardware specializes in tight tolerance precision machining of small to medium size parts in a wide variety of materials and quantities. Our technical staff can assist you in finding the right approach and cost effective solution for your production needs.

Contact us today to find out how we can be of service to you.

.jpg)

.jpg)

.jpg)