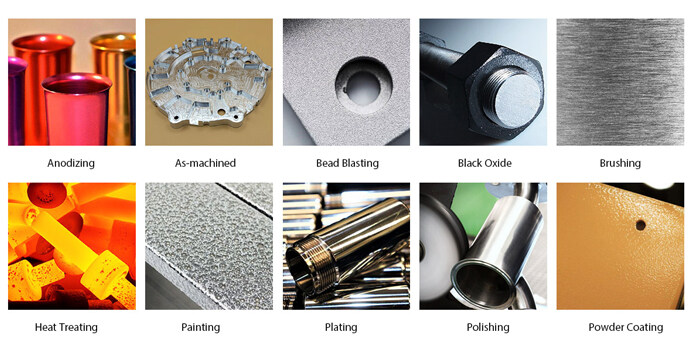

The secondary processing of aluminum lighting parts includes a series of finishes, such as anodizing, powder coating, plating, polishing, and so on. These stylish finishes are important for the visible part of aluminum's appearance, and the choice of finish often depends on the product application.

Anodizing

Anodizing is the most common finish treatment for lighting fixture aluminum parts, and aluminum is perfect for anodizing. It is an electrochemical process that transforms the metal surface into a decorative, durable, corrosion-resistant anodized surface that can be dyed in various colors and finishes.

Anodizing is accomplished by immersing aluminum in an acidic electrolyte and passing an electric current through the medium. The cathode is installed inside the anodizing tank, and aluminum acts as an anode, releasing oxygen ions from the electrolyte to combine with the aluminum atoms on the surface of CNC machined lighting parts.

In short, anodizing is a highly controlled oxidation process, which is an enhancement of a naturally occurring phenomenon.

Surface Treatment For Aluminum Lighting Parts

Advantages Of Anodizing Treatment

Tough - Anodizing uses the characteristics of aluminum alloy to create a thin yet strong surface. The anodized surface of anodized aluminum parts for lighting is extremely hard and corrosion-resistant, which can prolong the product's lifespan. So it is suitable for many applications in many industries, not just LED lighting accessories.

Durable - Most anodized products have a long service life, and anodizing is one of the best finishes that can withstand the test of time. As mentioned above, anodizing is a reactive finish that bonds to the underlying aluminum with complete adhesion and unmatched adherence that will not flake, chip, or peel over time.

Custom Anodized Aluminum Lighting Housing

Not Easy to Fade - Anodized aluminum parts for lighting have high color stability. Anodizing not only offers a large selection of colors, but the sealing process minimizes or eliminates color change, allowing anodized parts to remain as good as new for years. Also, anodized surfaces are very stable to UV light, will not chip or flake, and are easy to duplicate.

Easy to maintain - Scars and wear from handling, installation, frequent cleaning, and use are almost non-existent on anodized aluminum parts for lighting. Generally, cleaning anodized surfaces with mild soap and water is sufficient to restore the original appearance. Furthermore, a mild detergent is an excellent choice for more stubborn stains.

Cost-effective - Anodizing offers a broad range of colors and textures that provide aesthetic appeal while maintaining a metallic appearance. What’s more, the lower initial processing and maintenance costs make anodizing features brilliant long-term value. More importantly, the anodizing process enhances a naturally occurring oxide process, so it is a healthy and safe option that does not create any harmful or hazardous effects.

Conclusion

Don't forget that durability is another decisive factor when machining aluminum lighting parts, especially if the lighting fixture aluminum parts are used outdoors. And when LED lighting accessories are less conspicuous or for indoor use, a variety of cost-effective finishes are available. No matter what your requirements are, JeaSnn will work with you to find the best solution for aluminum lighting parts!

As a professional lighting fixture aluminum parts manufacturer in China, we offer a wide range of CNC machined lighting parts with various finish treatments. All in all, we take responsibility for all aspects of your project, from drawing to on-time delivery of your lighting fixture aluminum parts. Please feel free to contact us at info@aluminumlightingparts.com for more details about anodized aluminum parts for lighting!

.jpg)

.jpg)

.jpg)